AIAG Control Plan

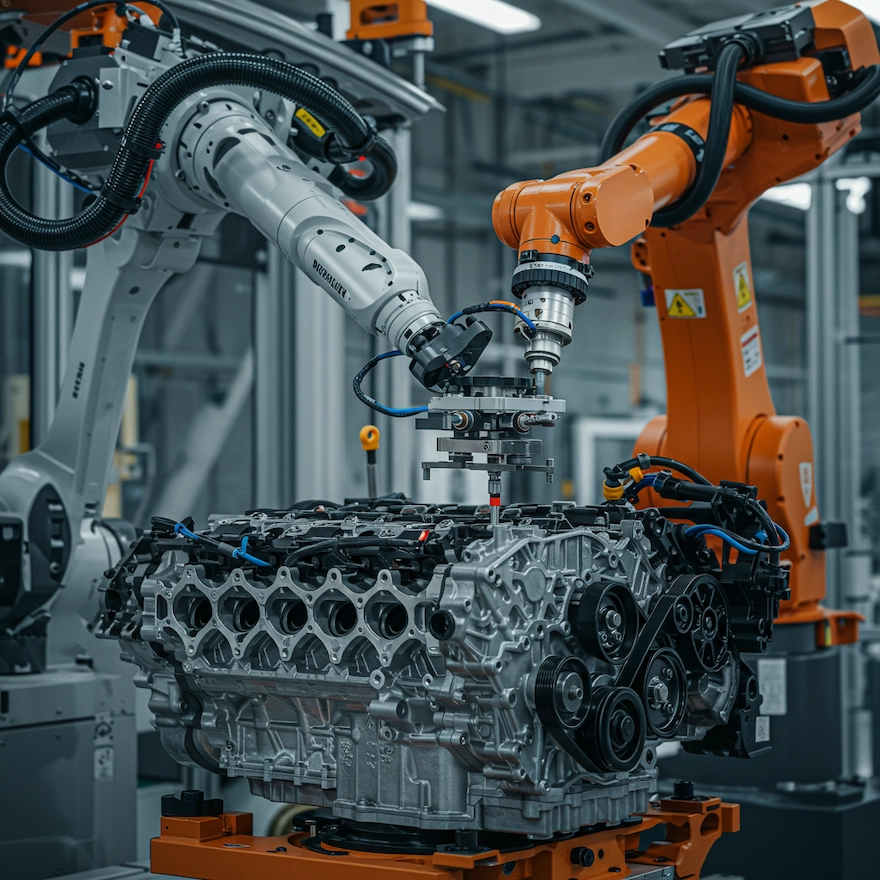

Master the AIAG Control Plan standard, a cornerstone of automotive quality requirements. This premier Malaysian program teaches robust automotive control plan development and process control documentation. Learn APQP integration and defect prevention strategies to ensure process stability assurance and production quality control. Elevate your quality management system for superior control plan effectiveness and move towards zero-defect manufacturing.

Focus of Master AIAG Control Plan Training: Best in Malaysia for Automotive Supplier Quality

Master control plan documentation for assured production launch

Our Mission & Vision

Provide effective training and solutions that grow competitiveness of our clients.

Highlights of Master AIAG Control Plan Training: Best in Malaysia for Automotive Supplier Quality

Optimize production and quality with practical AIAG Control Plan expertise.

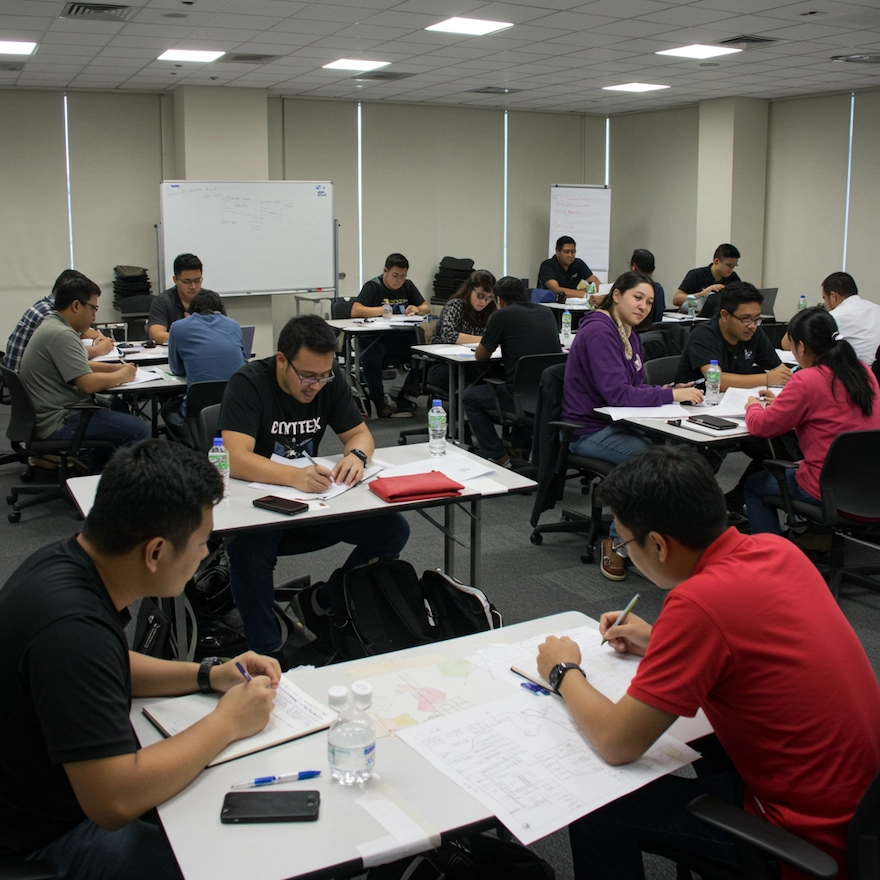

This program uniquely blends AIAG Control Plan expertise with practical, hands-on control plan development. Learn through real-world audit scenarios and automotive manufacturing examples to optimize process efficiency and defect prevention. Move beyond theory with interactive APQP workshops and collaborative exercises, ensuring immediate skills for production workflow optimization and operational performance improvement. Gain proven techniques from experienced automotive quality professionals.

Master AIAG Control Plans to optimize production and prevent defects. Gain practical expertise through real case studies and hands-on development workshops.

Frequently Asked Questions: 3C

FAQ 1. What COMPETENCY and skills will I gain from this training?

FAQ 2. Can the training be tailored or CUSTOMISED to our organizations specific needs?

FAQ 3. Will I receive a recognized qualification or CERTIFICATE?

Competency

Customization

Certificate

Master AIAG Control Plans for automotive supplier compliance.

This training provides mastery of AIAG Control Plans to ensure quality, meet automotive requirements, and integrate FMEA and APQP for robust production launches and defect prevention.